Training Course on Vision-Based Control Systems

Training Course on Vision-Based Control Systems focuses on the synergy between industrial cameras, image processing algorithms, and feedback control loops to achieve superior performance in manufacturing, robotics, quality inspection, and logistics.

Course Overview

Training Course on Vision-Based Control Systems

Introduction

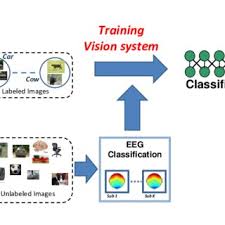

This specialized training course explores the rapidly evolving field of Vision-Based Control Systems, providing participants with the essential knowledge and practical skills to integrate and leverage computer vision for precise and intelligent automation. Training Course on Vision-Based Control Systems focuses on the synergy between industrial cameras, image processing algorithms, and feedback control loops to achieve superior performance in manufacturing, robotics, quality inspection, and logistics. Attendees will delve into concepts such as real-time object recognition, 3D vision, pose estimation, and the application of machine learning for visual inspection, preparing them for the demands of Industry 4.0 and smart factory environments.

As industries transition towards greater autonomy and precision, the demand for experts in Vision-Based Control (VBC) is escalating. This course is meticulously designed to empower engineers and technicians with the ability to design, implement, and optimize systems that use visual data for closed-loop control. Key topics include robot vision guidance, defective product detection, feature tracking, and the crucial aspects of lighting and optics. Through practical exercises, real-world case studies, and exposure to cutting-edge deep learning techniques for vision, participants will gain a competitive edge in developing and deploying next-generation automated solutions that significantly enhance efficiency, accuracy, and operational flexibility.

Course duration

10 Days

Course Objectives

- Comprehend the fundamental principles of computer vision and its application in industrial control.

- Design and implement effective vision systems for various industrial automation tasks.

- Select appropriate cameras, lenses, and lighting for optimal image acquisition in diverse environments.

- Develop and apply advanced image processing algorithms for feature extraction and analysis.

- Integrate vision data into feedback control loops for precise robotic manipulation and process control.

- Implement real-time object detection and recognition using traditional and deep learning methods.

- Perform 3D vision tasks, including depth perception, point cloud processing, and pose estimation.

- Understand and utilize machine learning techniques for visual inspection and quality control.

- Troubleshoot and optimize performance issues in vision-based control applications.

- Apply vision guidance for robotic systems in pick-and-place, assembly, and welding operations.

- Evaluate and select appropriate vision software libraries and hardware platforms.

- Ensure data integrity and security in networked vision systems and industrial environments.

- Drive innovation in manufacturing and automation through the strategic deployment of VBC systems.

Organizational Benefits

- Enhanced Automation Precision: Achieve higher accuracy in robotic and automated tasks.

- Improved Quality Control: Early detection of defects and reduced product waste.

- Increased Production Efficiency: Faster cycle times and optimized workflows.

- Reduced Operational Costs: Minimized manual inspection and rework.

- Greater Flexibility in Manufacturing: Adapt to diverse product variations with vision guidance.

- Safer Work Environments: Automation of hazardous tasks.

- Data-Driven Process Optimization: Insights from visual data for continuous improvement.

- Competitive Edge: Adoption of cutting-edge vision technology.

- Skilled Workforce: Empowered employees proficient in advanced vision systems.

- Accelerated Digital Transformation: Enabling smart factory initiatives.

Target Participants

- Automation Engineers

- Robotics Engineers

- Process Engineers

- Manufacturing Engineers

- Quality Control Engineers

- R&D Engineers

- Control System Engineers

- Machine Vision Specialists

- Systems Integrators

- Technicians involved in automation and quality inspection

Course Outline

Module 1: Fundamentals of Computer Vision for Control

- Introduction to Computer Vision: Core concepts, applications in industry, and control loops.

- Image Formation and Sensing: Digital cameras, image sensors, and pixel properties.

- Basic Image Processing Operations: Histograms, brightness, contrast, and color spaces.

- Vision System Architectures: Hardware components (cameras, frame grabbers, processors).

- Case Study: Setting up a basic vision system for presence/absence detection on an assembly line.

Module 2: Optics, Lighting, and Image Acquisition

- Lenses and Optical Principles: Focal length, depth of field, and distortion.

- Industrial Lighting Techniques: Backlight, diffuse, dark field, and structured light.

- Camera Selection and Calibration: Resolution, frame rate, sensor size, and intrinsic parameters.

- Image File Formats and Data Transfer: Efficient handling of visual data.

- Case Study: Optimizing lighting and lens selection for inspecting reflective surfaces.

Module 3: Image Preprocessing and Enhancement

- Noise Reduction Techniques: Filtering (Gaussian, Median, Bilateral) for clearer images.

- Geometric Transformations: Translation, rotation, scaling, and perspective correction.

- Image Segmentation: Thresholding, edge detection (Canny, Sobel), and region growing.

- Morphological Operations: Erosion, dilation, opening, and closing for feature manipulation.

- Case Study: Preprocessing images of electronic components to enhance features for inspection.

Module 4: Feature Extraction and Description

- Edge and Corner Detection: Harris, SIFT, SURF for robust feature identification.

- Blob Analysis: Extracting properties of connected regions (area, centroid, orientation).

- Line and Circle Detection: Hough Transform for geometric shape recognition.

- Texture Analysis: Describing surface patterns for material inspection.

- Case Study: Using blob analysis to count and sort small parts on a conveyor belt.

Module 5: Object Recognition and Identification

- Template Matching: Comparing unknown objects to known patterns.

- Pattern Recognition Algorithms: Machine learning basics for classification.

- Geometric Pattern Matching: Robust recognition despite partial occlusion or varying orientation.

- Barcodes and QR Codes: Decoding and utilizing encoded visual information.

- Case Study: Developing a system to identify different product variants on a production line.

Module 6: Vision-Based Measurement and Metrology

- Dimensional Gaging: Accurate measurement of object dimensions.

- Calibration for Measurement Accuracy: Ensuring precise real-world measurements from pixels.

- Surface Inspection: Detecting scratches, dents, and surface defects.

- Robotic Measurement Systems: Integrating vision for automated metrology.

- Case Study: Implementing a vision system for non-contact measurement of manufactured parts.

Module 7: 3D Vision and Depth Perception

- Stereo Vision: Principles of binocular vision and depth calculation.

- Structured Light Systems: Projecting patterns for 3D reconstruction.

- Time-of-Flight (ToF) Cameras: Directly measuring depth information.

- Point Cloud Processing: Working with 3D data for object recognition and pose.

- Case Study: Using a 3D vision system for bin-picking applications in robotics.

Module 8: Robot Vision Guidance

- Eye-in-Hand vs. Eye-to-Hand Configurations: Setup and calibration for robotic tasks.

- Pose Estimation and Tracking: Determining object position and orientation for robot control.

- Robot-Vision Calibration: Aligning camera and robot coordinate systems.

- Path Planning with Vision Feedback: Adapting robot movements based on visual data.

- Case Study: Guiding a robot arm to precisely pick and place randomly oriented objects.

Module 9: Machine Learning for Visual Inspection

- Supervised Learning for Classification: Training models to categorize images (e.g., good/bad parts).

- Unsupervised Learning for Anomaly Detection: Identifying unusual patterns without prior labels.

- Feature Learning with Neural Networks: Automating feature extraction.

- Deployment of ML Models in Vision Systems: Integrating trained models into industrial applications.

- Case Study: Training a machine learning model to detect subtle defects on product surfaces.

Module 10: Deep Learning for Computer Vision

- Convolutional Neural Networks (CNNs): Architectures for image classification and object detection.

- Object Detection Models: YOLO, Faster R-CNN, SSD for real-time applications.

- Image Segmentation with Deep Learning: Pixel-level classification (U-Net, Mask R-CNN).

- Transfer Learning in Vision: Reusing pre-trained models for new tasks.

- Case Study: Using a deep learning model for real-time quality control of complex assemblies.

Module 11: Real-Time Vision and Embedded Systems

- Real-time Image Processing: Optimizing algorithms for speed.

- Embedded Vision Platforms: NVIDIA Jetson, Raspberry Pi for compact solutions.

- FPGA-based Vision Systems: High-performance hardware for demanding applications.

- Parallel Processing for Vision: Utilizing GPUs and multi-core processors.

- Case Study: Developing an embedded vision system for high-speed inspection on a production line.

Module 12: Vision Software and Libraries

- OpenCV: Comprehensive open-source library for computer vision.

- Halcon, Cognex VisionPro, National Instruments Vision: Commercial vision software packages.

- Python for Computer Vision: Key libraries (NumPy, SciPy, scikit-image).

- Integration with PLCs and Industrial Controllers: Communication protocols and interfaces.

- Case Study: Implementing a vision application using OpenCV to control a sorting mechanism.

Module 13: Advanced Applications of Vision-Based Control

- Vision for Assembly Verification: Ensuring correct component placement.

- Surface Crack and Defect Detection: Automated inspection of critical parts.

- Medical Imaging and Analysis: Vision in diagnostics and surgical guidance.

- Autonomous Vehicle Vision: Perception systems for self-driving cars and industrial vehicles.

- Case Study: Developing a vision system for automated quality inspection of soldered joints on PCBs.

Module 14: System Integration and Deployment

- Interfacing Vision Systems with Robots and PLCs: Communication protocols (EtherNet/IP, Profinet).

- Designing User Interfaces for Vision Systems: Operator interaction and data visualization.

- Testing and Validation of Vision Systems: Ensuring robustness and reliability.