Training Course on Flow Assurance: Managing Flow Dynamics and Production Chemistry

Training Course on Flow Assurance: Managing Flow Dynamics and Production Chemistry delves into essential concepts such as fluid behavior, chemical reactions, flow modeling, and treatment techniques to combat production issues.

Course Overview

Training Course on Flow Assurance: Managing Flow Dynamics and Production Chemistry

Introduction

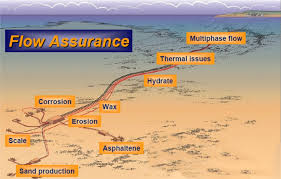

Flow assurance is a critical aspect of the oil and gas industry, ensuring the safe, efficient, and uninterrupted transportation of oil, gas, and other fluids from the production site to the refinery or storage facilities. The complexities involved in managing flow dynamics and production chemistry can impact both operational efficiency and cost. By understanding the principles of flow assurance, professionals can mitigate risks such as blockages, corrosion, hydrate formation, and scale buildup, thereby optimizing production processes and reducing downtime. This training course is designed to provide professionals with the in-depth knowledge and skills required to manage flow assurance challenges effectively, leveraging the latest technologies and strategies in the field.

This training program delves into essential concepts such as fluid behavior, chemical reactions, flow modeling, and treatment techniques to combat production issues. With the growing complexity of oil and gas operations, there is an increasing demand for experts capable of designing robust flow assurance strategies. The course also addresses real-world challenges like hydrate management, pipeline integrity, and multiphase flow, providing participants with the tools necessary to enhance productivity, reduce operational risks, and extend the lifespan of production facilities. By focusing on both theoretical knowledge and practical solutions, the course aims to equip professionals with the capabilities to maintain smooth operations in the challenging environment of energy production.

Course Duration

5 days

Course Objectives

- Understand the fundamental concepts of flow assurance and its significance in oil and gas production.

- Analyze fluid properties and their impact on flow behavior in pipelines and production systems.

- Develop skills in multiphase flow modeling and its role in designing flow assurance strategies.

- Learn to identify and mitigate risks such as hydrate formation, wax deposition, and scale buildup.

- Master the techniques of corrosion control and management in pipeline systems.

- Gain expertise in chemical treatments for enhancing flow and reducing operational downtime.

- Explore cutting-edge technologies used for real-time monitoring and flow optimization.

- Learn the application of dynamic simulation models for flow assurance decision-making.

- Understand the integration of production chemistry with flow dynamics for overall system efficiency.

- Study pipeline insulation techniques and their role in preventing temperature-related flow issues.

- Address environmental and safety concerns in the management of flow assurance issues.

- Develop strategies to optimize operational costs related to flow assurance activities.

- Apply industry best practices and case studies to solve common flow assurance challenges.

Organizational Benefits

- Enhanced Operational Efficiency: Organizations can reduce unplanned shutdowns and increase production uptime by managing flow dynamics and preventing common flow assurance issues.

- Cost Savings: Through effective risk management and optimized flow techniques, companies can cut down on maintenance costs and improve asset life cycle management.

- Safety & Compliance: A well-managed flow assurance strategy helps mitigate risks related to corrosion, hydrates, and scale, ensuring compliance with safety standards and reducing environmental impact.

- Improved Productivity: By optimizing flow in production systems, organizations can increase the throughput of their facilities and reduce bottlenecks.

- Competitive Advantage: Implementing cutting-edge flow assurance techniques can position companies ahead of competitors by demonstrating superior operational excellence.

Target Participants

- Flow Assurance Engineers

- Production Engineers

- Chemical Engineers

- Operations Managers in Oil & Gas

- Pipeline Integrity Engineers

- Maintenance Managers

- Safety Officers and Compliance Managers

- Environmental Engineers in Energy Sector

Course Outline

Module 1: Introduction to Flow Assurance

- Basics of flow assurance and its relevance in oil and gas production.

- Key flow dynamics concepts: pressure, temperature, and flow rate.

- Flow assurance challenges: hydrates, waxes, and scaling.

- Importance of production chemistry in maintaining flow.

- Impact of multiphase flow on pipeline efficiency.

Module 2: Fluid Behavior and Flow Modeling

- Principles of fluid mechanics in multiphase flow.

- The role of fluid viscosity, density, and composition in flow.

- Introduction to computational fluid dynamics (CFD) modeling.

- Multiphase flow simulation tools and techniques.

- Case studies on successful flow modeling implementations.

Module 3: Hydrate Formation and Management

- Understanding hydrate formation in pipelines.

- Techniques for preventing and managing hydrate blockages.

- Role of chemicals in hydrate inhibition.

- Real-time monitoring tools for hydrate management.

- Case studies of hydrate management in challenging environments.

Module 4: Corrosion Control and Prevention

- Types of corrosion in pipelines and production systems.

- Key factors influencing corrosion rates.

- Strategies for corrosion inhibition and mitigation.

- Importance of coating and cathodic protection.

- Case studies on successful corrosion control programs.

Module 5: Scale and Wax Deposition Management

- Understanding scale and wax formation in pipelines.

- Chemical and mechanical treatments to prevent deposits.

- Monitoring techniques for scale and wax buildup.

- Case studies on effective deposition control.

- Tools and technologies for scale and wax management.

Module 6: Advanced Chemical Treatments for Flow Assurance

- Overview of chemical treatments used in flow assurance.

- Types of chemicals for scale, wax, and hydrate management.

- Chemical injection systems and their applications.

- Assessing the effectiveness of chemical treatments.

- Safety protocols for chemical handling and storage.

Module 7: Real-Time Monitoring and Optimization

- Importance of monitoring flow assurance in real-time.

- Technologies for flow measurement and data collection.

- Using AI and machine learning for flow optimization.

- Remote sensing and automated systems for pipeline management.

- Key performance indicators for effective monitoring.

Module 8: Safety, Environmental Impact, and Compliance

- Safety considerations in flow assurance activities.

- Environmental risks and mitigation strategies.

- Regulatory compliance in flow assurance practices.

- Sustainable practices for long-term flow assurance.

- Developing safety protocols for flow assurance operations.

Training Methodology

This training course will employ a blended learning approach, incorporating:

- Interactive lectures and presentations by industry experts.

- Case studies and real-world examples of sustainable ammonia projects.

- Group discussions and collaborative problem-solving sessions.

- Practical exercises and simulations (where applicable).

- Q&A sessions and opportunities for networking.

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.