Training Course on Digital Twin Technology for Oil and Gas Asset Optimization

Training Course on Digital Twin Technology for Oil & Gas Asset Optimization equips industry professionals with the tools and strategies needed to harness digital twins for asset optimization, predictive maintenance, real-time monitoring, and enhanced operational efficiency in upstream, midstream, and downstream operations.

Skills Covered

Course Overview

Training Course on Digital Twin Technology for Oil & Gas Asset Optimization

Introduction

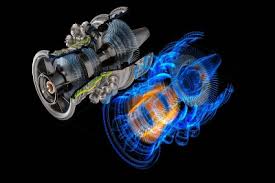

The Oil & Gas (O&G) industry is undergoing a massive transformation powered by Industry 4.0, and at the core of this revolution is Digital Twin Technology. A Digital Twin is a dynamic virtual model of a physical asset, system, or process that uses real-time data, AI, and advanced analytics to mirror the behavior of its real-world counterpart. Training Course on Digital Twin Technology for Oil & Gas Asset Optimization equips industry professionals with the tools and strategies needed to harness digital twins for asset optimization, predictive maintenance, real-time monitoring, and enhanced operational efficiency in upstream, midstream, and downstream operations.

With increasing demands for energy efficiency, cost control, and sustainability, digital twins are becoming essential to achieve maximum equipment uptime, risk reduction, and data-driven decision-making. This training provides hands-on, strategic, and technical insights into how digital twins can integrate IoT, AI, cloud computing, and machine learning to optimize O&G asset performance. It is ideal for professionals seeking to upskill in digital transformation, smart operations, and data-centric engineering for future-ready energy infrastructure.

Course Objectives

- Understand the fundamentals and architecture of Digital Twin Technology.

- Explore the applications of digital twins in oil and gas asset optimization.

- Develop strategies for predictive maintenance using real-time data.

- Learn to integrate AI, IoT, and machine learning into asset models.

- Analyze digital twin use in risk mitigation and safety enhancement.

- Examine cloud computing solutions in twin-enabled ecosystems.

- Identify data sources and interoperability for digital twins.

- Apply data visualization and analytics for performance insights.

- Design lifecycle strategies using Digital Twin Lifecycle Management (DTLM).

- Assess CAPEX and OPEX benefits of digital twin implementation.

- Understand cybersecurity risks in digital twin infrastructures.

- Review key KPIs for asset performance monitoring via digital twins.

- Evaluate sustainability impacts and net-zero alignment through twin tech.

Target Audiences

- Oil & Gas Engineers

- Maintenance & Reliability Engineers

- Digital Transformation Managers

- Data Scientists in Energy Sector

- Asset Integrity Professionals

- Operations & Plant Managers

- IT Architects and System Integrators

- Corporate Strategy & Innovation Leaders

Course Duration: 10 days

Course Modules

Module 1: Introduction to Digital Twin Technology

- Definition and components of a digital twin

- Evolution from simulation to real-time twins

- Core architecture and data requirements

- Benefits across the oil & gas value chain

- Real-world industry use cases

- Case Study: Shell’s digital twin implementation in offshore platforms

Module 2: Building Blocks of Digital Twins

- IoT sensors and edge computing

- Integration with enterprise asset management systems

- Data ingestion and processing pipelines

- Virtual and augmented reality applications

- AI/ML for behavior modeling

- Case Study: Chevron’s digital twin for compressor optimization

Module 3: Digital Twin for Upstream Asset Optimization

- Reservoir modeling and real-time drilling optimization

- Virtual modeling of subsurface assets

- Equipment health monitoring

- Real-time decision support systems

- Enhanced oil recovery (EOR) via data insights

- Case Study: BP’s reservoir twin success story

Module 4: Digital Twin for Midstream Operations

- Pipeline monitoring and flow optimization

- Leak detection and predictive diagnostics

- Pressure and corrosion modeling

- SCADA integration and visualization

- Scheduling and logistics optimization

- Case Study: TransCanada’s twin-enabled pipeline monitoring

Module 5: Digital Twin for Downstream Efficiency

- Refinery asset management via digital twins

- Process control optimization

- Turnaround and shutdown planning

- Emission tracking and compliance

- Workforce training with VR twins

- Case Study: ExxonMobil’s smart refinery operations

Module 6: Predictive Maintenance and Reliability

- Asset failure modeling using historical data

- Condition-based and predictive analytics

- Root cause analysis integration

- Remote diagnostics and intervention

- Reduction of unplanned downtimes

- Case Study: TotalEnergies’ turbine maintenance with twins

Module 7: AI and Machine Learning Integration

- Supervised and unsupervised ML for asset performance

- Reinforcement learning in operation scenarios

- Training models with live asset data

- Anomaly detection via deep learning

- Real-time AI-driven alerts

- Case Study: Digital twin AI modeling in Equinor platforms

Module 8: Cloud and Edge Computing in Digital Twins

- Architecture of hybrid cloud-edge systems

- Real-time data streaming and storage

- Network and latency considerations

- Cost-effective scaling strategies

- Vendor platforms comparison (AWS, Azure, Google)

- Case Study: Schlumberger’s twin deployment on AWS

Module 9: Cybersecurity and Risk Management

- Cyber threats in twin-integrated systems

- Access control and data encryption

- Industrial control systems (ICS) security

- Compliance frameworks (NIST, ISO)

- Secure digital twin deployment best practices

- Case Study: Cybersecurity breach simulation in twin models

Module 10: Data Visualization and KPI Monitoring

- Dashboards for real-time asset monitoring

- Visual twin overlays and 3D modeling

- KPI selection for performance tracking

- Integration with ERP and CMMS

- Decision dashboards for executive view

- Case Study: Repsol’s performance twin dashboards

Module 11: Digital Twin Lifecycle Management

- From design to decommissioning lifecycle modeling

- Configuration and version management

- Synchronization with physical assets

- Role of PLM (Product Lifecycle Management) tools

- Cost optimization over lifecycle

- Case Study: Lifecycle tracking of offshore rigs

Module 12: Regulatory Compliance and Sustainability

- Environmental impact tracking

- Emissions forecasting and modeling

- Compliance reporting automation

- ESG alignment and twin models

- Simulation for carbon-neutral operations

- Case Study: ENI’s sustainability initiative with digital twins

Module 13: Vendor and Tool Ecosystem

- Leading digital twin software platforms

- Proprietary vs open-source tools

- Vendor selection criteria

- Cost-benefit analysis tools

- Customization and interoperability

- Case Study: Implementation comparison of AVEVA vs Siemens

Module 14: ROI and Business Case Development

- Calculating ROI from twin investments

- Downtime reduction impact analysis

- Productivity and efficiency gains

- Value justification to stakeholders

- Aligning with strategic goals

- Case Study: ROI assessment in Total's refinery

Module 15: Future Trends and Emerging Technologies

- Cognitive twins and generative AI

- Blockchain integration for audit trails

- Quantum computing potential

- Industry 5.0 and human-digital co-creation

- Autonomous systems and robotics

- Case Study: Next-gen twins at Saudi Aramco facilities

Training Methodology

- Interactive instructor-led sessions with industry practitioners

- Live demonstrations of digital twin platforms and tools

- Case study deep dives with discussion activities

- Hands-on simulation labs using digital twin environments

- Knowledge assessments and real-world scenario challenges

- Participant collaboration via group projects and feedback

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.