Computational Fluid Dynamics (CFD) in Food Equipment Design Training Course

Computational Fluid Dynamics (CFD) in Food Equipment Design Training Course provides a practical and comprehensive approach to applying CFD techniques in the food industry to improve product quality, enhance process efficiency, and ensure food safety.

Skills Covered

Course Overview

Computational Fluid Dynamics (CFD) in Food Equipment Design Training Course

Introduction

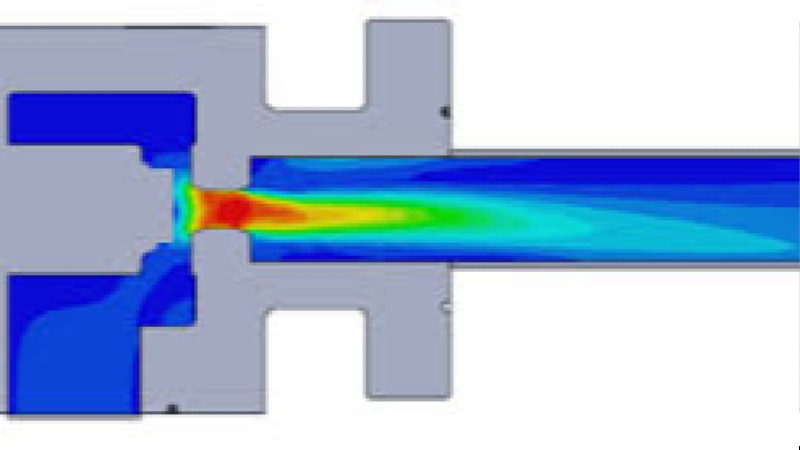

Computational Fluid Dynamics (CFD) has become an essential tool in the design and optimization of modern food equipment, offering engineers and researchers the ability to analyze fluid flow, heat transfer, and mass transfer in highly complex systems. Computational Fluid Dynamics (CFD) in Food Equipment Design Training Course provides a practical and comprehensive approach to applying CFD techniques in the food industry to improve product quality, enhance process efficiency, and ensure food safety. By incorporating simulation-based strategies, participants will gain the skills needed to create energy-efficient and sustainable food equipment designs.

The program is tailored to introduce the fundamentals of CFD, advanced modeling concepts, and the latest industry applications. Participants will learn how CFD simulations can predict system performance, reduce experimental costs, and accelerate design timelines. Through real-world case studies, this course highlights the transformative role of CFD in food processing, packaging, refrigeration, and thermal equipment development. It provides industry professionals with the knowledge to bridge engineering theory with computational practice, aligning with current trends in digitalization, sustainability, and smart manufacturing in the food industry.

Course Objectives

- Understand the principles of Computational Fluid Dynamics and its relevance in food equipment design.

- Apply CFD modeling techniques to analyze fluid flow, heat transfer, and mass transfer.

- Evaluate design alternatives for food equipment using CFD simulations.

- Optimize food equipment designs for energy efficiency and sustainability.

- Gain hands-on experience in commercial CFD software for food industry applications.

- Learn to interpret and validate CFD simulation results.

- Develop skills to integrate CFD into product development cycles.

- Apply CFD in refrigeration, freezing, drying, and thermal processing systems.

- Improve process safety and compliance using CFD models.

- Reduce prototyping and experimental costs with virtual simulation.

- Explore CFD-driven innovations in packaging and material handling.

- Address real-world challenges in scaling food equipment designs with CFD.

- Align CFD applications with Industry 4.0 and digital transformation strategies.

Organizational Benefits

- Enhanced product quality through optimized equipment designs.

- Reduction in operational and prototyping costs.

- Improved energy efficiency and sustainability in processes.

- Faster time-to-market with simulation-driven design.

- Increased compliance with safety and regulatory standards.

- Greater competitiveness through advanced innovation.

- Reduced downtime and maintenance costs.

- Improved decision-making using predictive modeling.

- Scalability of equipment design for industrial applications.

- Strengthened workforce skills aligned with modern industry needs.

Target Audiences

- Food process engineers

- Equipment design engineers

- R&D professionals in food technology

- Quality and safety managers

- Manufacturing and production managers

- Industrial automation specialists

- Academic researchers in food science and engineering

- Sustainability and energy efficiency consultants

Course Duration: 5 days

Course Modules

Module 1: Introduction to CFD in Food Industry

- Fundamentals of Computational Fluid Dynamics

- Importance of CFD in food equipment design

- Overview of fluid mechanics and heat transfer in food systems

- Software tools and interface basics

- Limitations and challenges of CFD in food processes

- Case study: CFD in fluid mixing for beverage processing

Module 2: CFD Fundamentals and Governing Equations

- Conservation of mass, momentum, and energy

- Numerical methods for solving CFD problems

- Grid generation and mesh quality

- Boundary conditions in food system simulations

- Error sources and convergence criteria

- Case study: CFD analysis of heat exchangers in dairy industry

Module 3: Heat Transfer Applications in Food Equipment

- Heat conduction, convection, and radiation modeling

- Simulation of pasteurization and sterilization processes

- Optimizing thermal equipment design

- Impact of CFD on food safety standards

- Energy efficiency in thermal processing

- Case study: CFD in continuous pasteurizer design

Module 4: Mass Transfer and Multiphase Flows

- Principles of diffusion and evaporation in food systems

- Modeling multiphase flows in mixers and reactors

- CFD in drying and freezing applications

- Predicting phase change and product quality

- Challenges in simulating multiphase systems

- Case study: CFD in spray dryer design

Module 5: CFD in Refrigeration and Freezing Equipment

- Modeling airflow in cold storage facilities

- Heat transfer in freezing processes

- Optimizing refrigeration cycles with CFD

- Energy-saving strategies for refrigeration units

- Food preservation and safety benefits of CFD

- Case study: CFD in blast freezer optimization

Module 6: CFD for Food Packaging Design

- Fluid-structure interaction in packaging processes

- Thermal and airflow analysis in packaging systems

- Reducing packaging defects with CFD simulations

- Designing packaging for energy and material savings

- CFD for shelf-life and quality assessment

- Case study: CFD in modified atmosphere packaging

Module 7: Advanced CFD Applications in Food Processing

- Non-Newtonian flow modeling in food materials

- Turbulence modeling in mixing and agitation processes

- CFD for fermentation and biochemical processes

- Virtual prototyping of complex systems

- Integration with machine learning for process prediction

- Case study: CFD in chocolate tempering

Module 8: Industrial Case Studies and Future Trends

- Best practices in industrial CFD applications

- Challenges in scaling CFD to large food plants

- Integration of CFD with Industry 4.0 technologies

- Role of CFD in sustainable food engineering

- Emerging CFD tools and trends in digitalization

- Case study: CFD-driven design of next-generation food equipment

Training Methodology

- Instructor-led interactive lectures

- Hands-on CFD simulation exercises using commercial software

- Real-world case studies and group discussions

- Practical assignments to reinforce learning

- Q&A sessions to address specific industrial challenges

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.