Advanced Filtration Techniques for Clarification Training Course

Advanced Filtration Techniques for Clarification Training Course is designed to provide in-depth knowledge of modern filtration systems, cutting-edge technologies, and process optimization methods that enhance product purity, yield, and consistency.

Skills Covered

Course Overview

Advanced Filtration Techniques for Clarification Training Course

Introduction

Filtration is a critical process across multiple industries, including biotechnology, food and beverage, water treatment, and pharmaceuticals. Advanced Filtration Techniques for Clarification Training Course is designed to provide in-depth knowledge of modern filtration systems, cutting-edge technologies, and process optimization methods that enhance product purity, yield, and consistency. The course emphasizes the scientific principles of clarification, filtration media selection, membrane performance, and system validation. Participants will gain hands-on understanding of process troubleshooting, performance evaluation, and regulatory compliance for filtration applications.

This specialized program integrates technical insights with practical implementation, ensuring participants acquire both theoretical competence and real-world operational expertise. By learning advanced clarification strategies, participants will be prepared to enhance product quality, reduce production downtime, and optimize process efficiency. The course covers aspects of microfiltration, depth filtration, crossflow systems, and nanofiltration for diverse industry applications, aligning with current sustainability and efficiency trends in global manufacturing.

Course Objectives

1. Understand the fundamental principles of filtration and clarification processes.

2. Analyze various filtration media and their compatibility with process requirements.

3. Learn membrane selection and system configuration for enhanced filtration efficiency.

4. Evaluate pre-filtration techniques for improving downstream processing.

5. Identify troubleshooting strategies for common filtration issues.

6. Implement process optimization techniques for sustainable production.

7. Explore automation and digital control in modern filtration systems.

8. Examine validation and regulatory compliance for critical filtration processes.

9. Apply particle size analysis and flow dynamics in clarification systems.

10. Integrate advanced membrane technologies for high-clarity outputs.

11. Develop preventive maintenance schedules for long-term system reliability.

12. Assess the environmental and economic benefits of advanced filtration technologies.

13. Utilize data-driven methods to monitor filtration performance trends.

Organizational Benefits

ΓÇó Improved product consistency and quality assurance.

ΓÇó Reduced operational costs through optimized filtration systems.

ΓÇó Enhanced compliance with global safety and quality standards.

ΓÇó Minimized process downtime through predictive maintenance.

ΓÇó Increased productivity and yield efficiency.

ΓÇó Improved sustainability and resource conservation.

ΓÇó Greater understanding of emerging filtration technologies.

ΓÇó Better control over contamination and process variability.

ΓÇó Strengthened workforce technical competencies.

ΓÇó Elevated organizational competitiveness in the global market.

Target Audiences

ΓÇó Process Engineers and Technicians

ΓÇó Quality Assurance and Control Professionals

ΓÇó Production Managers and Supervisors

ΓÇó Bioprocessing Specialists

ΓÇó Food and Beverage Technologists

ΓÇó Water Treatment Engineers

ΓÇó Laboratory Scientists and Researchers

ΓÇó Environmental and Sustainability Managers

Course Duration: 5 days

Course Modules

Module 1: Fundamentals of Filtration and Clarification

ΓÇó Principles of particle separation and fluid dynamics

ΓÇó Types and mechanisms of filtration

ΓÇó Key parameters affecting clarification

ΓÇó Industrial applications of clarification techniques

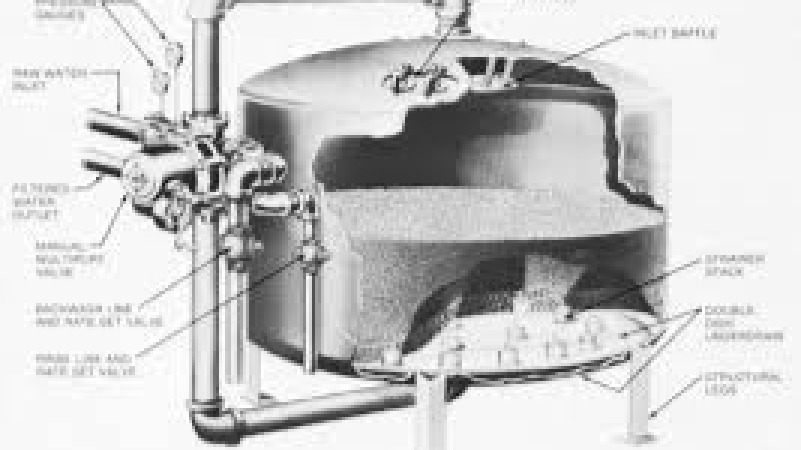

ΓÇó Equipment overview and setup procedures

ΓÇó Case Study: Optimization of clarification in beverage production

Module 2: Filtration Media and Membrane Selection

ΓÇó Properties and classification of filtration media

ΓÇó Selection criteria for various filtration needs

ΓÇó Membrane configurations and pore size relevance

ΓÇó Material compatibility and performance evaluation

ΓÇó Cost-benefit analysis for membrane systems

ΓÇó Case Study: Membrane selection in pharmaceutical filtration

Module 3: Depth Filtration and Microfiltration Systems

ΓÇó Design and operation of depth filters

ΓÇó Microfiltration process characteristics

ΓÇó Performance validation and integrity testing

ΓÇó Handling fouling and filter blockage

ΓÇó Scaling-up from pilot to industrial level

ΓÇó Case Study: Depth filtration in biopharmaceutical clarification

Module 4: Crossflow and Tangential Flow Filtration

ΓÇó Principles and advantages of crossflow filtration

ΓÇó Design considerations for system optimization

ΓÇó Process control and automation techniques

ΓÇó Membrane cleaning and reusability assessment

ΓÇó Energy efficiency improvement approaches

ΓÇó Case Study: Tangential flow filtration in protein clarification

Module 5: Nanofiltration and Ultrafiltration Applications

ΓÇó Differences between ultrafiltration and nanofiltration

ΓÇó Membrane cut-off and molecular weight considerations

ΓÇó Industrial-scale applications and efficiency gains

ΓÇó Concentration polarization and mitigation strategies

ΓÇó Filtrate recovery and reuse approaches

ΓÇó Case Study: Nanofiltration for water and wastewater treatment

Module 6: Process Optimization and Troubleshooting

ΓÇó Identification of process bottlenecks

ΓÇó Real-time monitoring and control systems

ΓÇó Predictive maintenance practices

ΓÇó Integration of automation for process stability

ΓÇó Troubleshooting common operational issues

ΓÇó Case Study: Reducing filtration cycle time in dairy processing

Module 7: Validation, Compliance, and Safety

ΓÇó Filtration validation protocols and documentation

ΓÇó Regulatory requirements and industry standards

ΓÇó Clean-in-place (CIP) and sterilization procedures

ΓÇó Safety practices in filtration operations

ΓÇó Environmental and waste management compliance

ΓÇó Case Study: Regulatory compliance in sterile filtration

Module 8: Emerging Technologies and Future Trends

ΓÇó Smart filtration systems and digital monitoring

ΓÇó AI and IoT integration in filtration control

ΓÇó Sustainable materials for eco-friendly filtration

ΓÇó Modular and compact system designs

ΓÇó Future innovations in membrane technology

ΓÇó Case Study: Automation in next-generation clarification systems

Training Methodology

ΓÇó Instructor-led presentations and interactive discussions

ΓÇó Demonstrations of filtration systems and equipment handling

ΓÇó Practical laboratory exercises and case study analysis

ΓÇó Group activities and peer-based problem-solving sessions

ΓÇó Assessments and feedback for skill validation

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.